2 Valve Manifold Pipe to Pipe Straight Type

Fastech Global offers a variety of 2 Valve instrument manifolds. The 2 Valve manifolds are designed for static pressure and liquid level applications. These manifolds are available in traditional and compact body designs. Manifold connections include female tube fittings, pipe ends (NPT and ISO 228/1), and flanges (MSS SP-99) in 1/2 and 3/4 in. and 12 mm sizes

We are the trusted name in the industry when it comes to theStockists & Supplier of valves, fittings and industrial couplings with adapters. We have served a wide variety of industrial sectors, and supply products which conform to industry standard requirements and ensure safety and system efficiency with their precision design. We offer an extensive product portfolio, and are also trusted manifold valve Stockists & Supplier, who offer reliable products for high end system efficiency. We understand the importance of durable quality in industrial valve and fitting design, and that is why we never compromise on quality.

Material testing has evolved into a significant part of all-male flare elbow development. The checking is always carried out to ensure that the product is not supplied with low quality. The tests are effective material recognition tests, pitting resistance tests, and hardness tests. Other measurements include flattening testing, mechanical testing, flammable testing, chemical testing, macro testing, and micro testing.The documents given to domestic and foreign customers are only intended to ensure that product quality is not lacking. The manufacturing is carried out efficiently to provide better product quality, and all documents are given to the customer. It is certified fumigation, invoice for industrial use, a heat treatment map, quality assurance plan, test raw material report, traceability report for products, etc.

Application

- Chemicals industry

- Fats and fertilizer industry

- Ship building

- Construction industry

Key Features

- Some of the key features of our superior quality high precision manifold valve design are Units duly designed to withstand system static pressure.

- The manifold valves are Stockists & Supplier to endure all differential pressure and liquid level application needs.

- Units have been Stockists & Supplier according to a compact assembly design. This translates into complete products which have a reduced weight and size.

- The design and manufacturing details of the valve manifold units ensure fewer chances of potential leak points.

- All units undergo extensive testing procedures to assess quality and precision before being supplied to customers.

- Units are available in a stainless steel 316 material series design.

- The units have been Stockists & Supplier to ensure easy installation and hassle free maintenance in aggressive industrial systems.

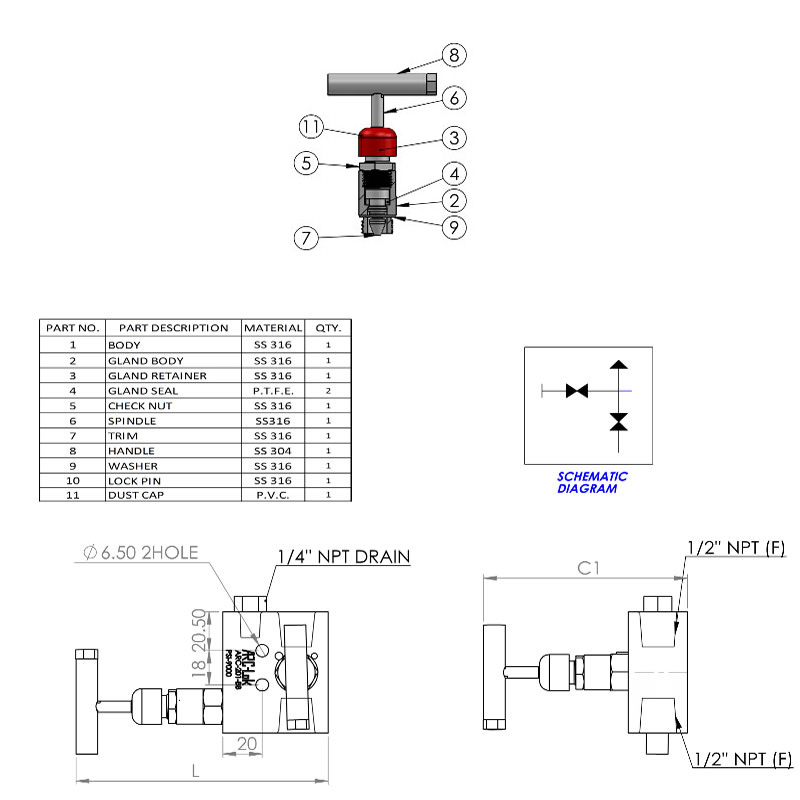

Bonnet Assembly

- Bonnet : back seated blow out proof.

- Spindle : ground and thread rolled. Packing below thread.

- Spindle Tip : non-rotating tip shut-off type & soft seated.

- Dust cap : dust cap protects stem threads from external contamination heat code traceability.

Typical Design And Dimension

Technical Specification

| Size : 1/4" & 1/2" & 3/4" Custom size available as per requirement |

|

| End Connection : NPT, BSPT, BSP & Socket Weld. | |

| Working Pressure : 6000 psi (413 bar) | |

| Temperature Rating : PTFE 450° f(232°c) Grafoil 700° f (371°c") | |

| Optional sour gas service valves are available confirming to nace mr-01-75 | |

| Stem Packing : PTFE, Grafoil. | |

| Orifice : ø4.7 | |

| All valves are 100% factory tested prior to shipment. |

Material of Construction

Monel :Grade: Monel 400, Monel K500, Monel R-405

Nickel :

Grade: Nickel 200, Nickel 201

Inconel :

Grade: Inconel 600, Inconel 601, Inconel 625, Inconel 718

Incoloy :

Grade: Incoloy 800, Inconel 800H, 800HT

Hastalloy :

Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X

Titanium :

Grade: Gr1, Gr2, Gr3, Gr5, Gr7, Gr11

Stainless Steel :

Grade: ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 304H, 316H, 316/316L, 321, 330, 347, 309/S, 310/S, 317/L, 333, 410/S, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel :

Grade: ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70

Duplex Steel:

Grade: ASTM / ASME A/SA 182 UNS F44, F45, F51, F53, F55, F60, F61

Alloy Steel:

Grade : ASTM SA 182 - E25, E26, E27, E28, E29B, E30B, E39B, E40B, E36B, E36C, E41B, AISI4130, AISI4140, AISI4340, 42CRMO4, 16MNCR5, 20MNCR5, 21CrMoV57, EN353, EN354, F11, F22, F91, F9, P11, P22, P91, P9, P5, P92, EN42J, EN8, EN19

Testing

- Pneumatic seat test is performed at 1/4 of working pressure. Hydrostatic shell test is performed at 1.5 times the working pressure optional test are available upon request.